|

Low maintenance and versatile!

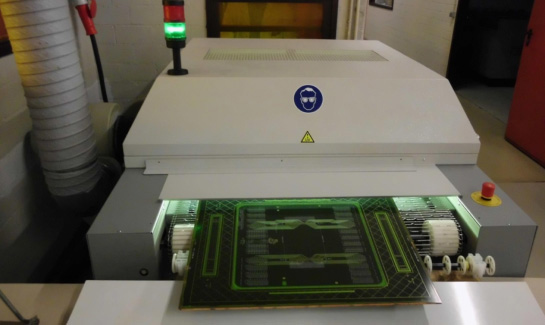

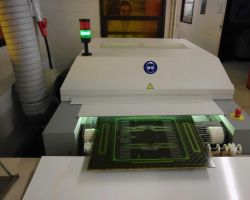

UV bump with metal-grid belt conveyor for mass production of printed circuit boards and substrates.

APPLICATIONS

UV cross-linking of photosensitive solder mask before or after thermal Final Cure for binding free photo initiators and improvement of the final properties of the solder resist

| UV bump with parallel belt transport |

| |

|

|

Bändertransport mit Transportüberwachung bei Überquerung

der unteren UV-Strahlereinheit |

| |

Click on the images to enlarge... Click on the images to enlarge... |

PROCESS DATA

Photoinitiators in the soldermask required for UV exposure are partly cross-linked during exposure process. The UV cross-linking in the UV-bump links a large part of the excess initiators and improves the surface properties of the solder resist considerably in terms of solvent resistance, surface resistance, solderability and contamination.

Depending on the equipment a UV dose of 500 - to 4,000 mJ / cm ² is applied on the solder resist.

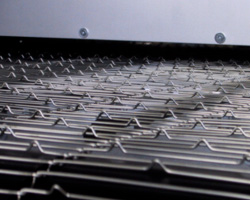

| UV bump with metal-grid belt conveyor |

| |

|

|

|

Metallgliederband mit punktförmiger Auflage für eine vollständige

Unterstrahlung der Leiterplattenunterseite |

| |

Click on the images to enlarge... Click on the images to enlarge... |

SPECIFICATIONS

Horizontal transport system of 10 parallel transport belts or metal metal grid belt, one or two UV lamps above and below the transportation according to the required belt speed and UV dose, PCB maximum width 720 mm, UV energy continuously adjustable from 40 - 100%, UV dose (each UV lamp 120W/cm) at 4.5 m / min and 100% UV-power: 1.500 mJ / cm ², PLC control for control and monitoring of program memory and continuous UV power meter with limit Alarm, reduced thermal stress in particular thin printed circuit boards using selectively filter reflectors and electronic cooling system.

| UV bump with metal grid belt transport in special design Slimsize |

| |

|

|

|

Sonderausführung Slimsize für minimalen Platzbedarf |

| |

Click on the images to enlarge... Click on the images to enlarge... |

FEATURES

UV cross-linking double-sided, simultaneously in fast horizontal continuous run, controlled delivery of UV dose, flexible adaptation to different process requirements with program stored in the PLC.

| UV-bump in production |

| |

|

|

|

UVUV-bump double-sided

with belt transport before thermal final curing oven

in a circuit board production |

UV-Nachvernetzungsanlage doppelseitig

mit Metallglieder-Transport

in einer Leiterplattenproduktion |

| |

| |

|

|

UV-bump type Slimsize in a Final Curing Line BELTROTHERM for soldermask

|

| |

Click on the images to enlarge... Click on the images to enlarge... |

| |

We are happy to inform you about our products and services.

Phone: +49 (0) 911 529 96 20 or by email: elegt@elget.de |

|